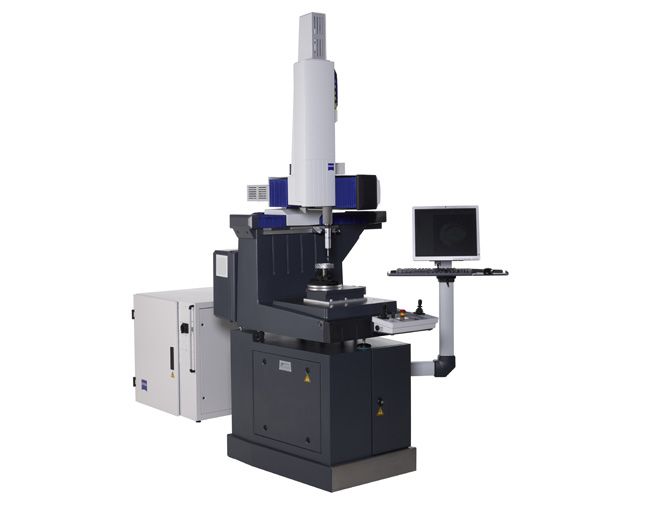

DuraMax

The right measuring equipment for the shopfloor.

The ability to measure quickly and accurately and the flexibility to react to changes are essential in the machining and tooling industry. Fixed gages and inspection equipment are no longer economical. DuraMax is your answer.

Key features

Made for production

-

-Complete CNC coordinate measuring machine; replaces many gages

-

-Measure with temperature stability up to to +30ºC

-

-Minimal space requirements; easy setup

Well-equipped standard configuration

-

�-Configured with scanning

Made to measure

-

-�Easy to use; can be loaded from three sides

-

-Practical stylus rack

-

-Low space requirements; more room to work

Machine technology

Reliable drive technology

-

-Completely covered guideways

-

-Integrated damping system

-

-Compensation of guideway errors (CAA corrected)

Technology from Carl Zeiss, the market leader

-

-C99 controller technology

-

-VAST XXT scanning sensor

-

-CALYPSO measuring software

-

-Fast startup

-

-No special installation or power requirements

Sensor systems

-

-VAST XXT scanning sensor from the technology leader

-

-Probe for single-point measuring and scanning

-

-Stylus receptacle for CNC-guided stylus change

-

-Adapter plate with 25 mm diameter for optimal reproducibility

Size

|

DuraMax

|

Measuring Range X× Y× Z[mm]

|

|

500 x 500 x 500

|

|

Working environmental temperature:18~30℃

|

|

Lenght measuring error(μm): 2.4 + L/300*Start

|

|

* - L = measuring lenght in mm

|

- Based on equipment specifications, with the probe and the use of the environment, the accuracy varies

Sensing system